P350 Laser Profiler Kit

RM0.00

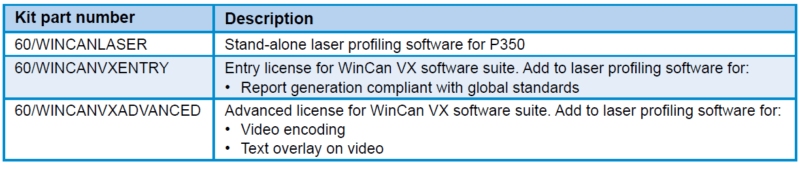

The laser profilers can be ordered as kits that provide all the parts needed to fit the laser profiler to the P350 system cameras and to adjust it before use.

Buying Guide: Check the type of your camera, then choose a kit that suits your camera.

Need assistance? Click here and send us your enquiry. We will be in-touch soon.

| Kit Part Number | Description | Fitting |

| 60/LASER-LG-PT | Variable laser profiler kit | P350 Pan & Tilt camera |

| 60/LASER-LG-PTZ | Variable laser profiler kit | P350 Pan, Tilt & Zoom camera |

| 60/LASER-SM-PT | Fixed laser profiler kit | P350 Pan & Tilt camera |

| 60/LASER-SM-PTZ | Fixed laser profiler kit | P350 Pan, Tilt & Zoom camera |