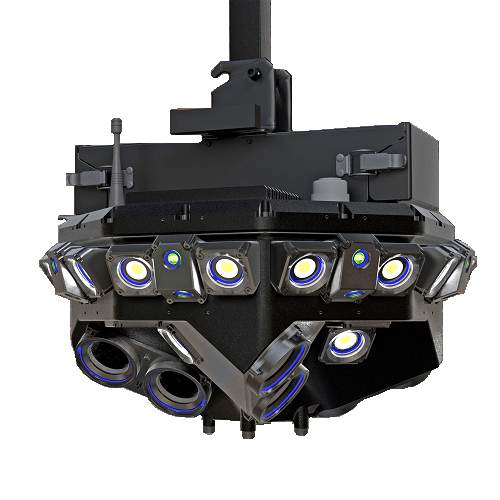

Cues Spider 3D Manhole Scanner

Cues Portable 3D Wireless Manhole Scanner.

Inspections and surveys of pipelines, wet wells, manholes, sewer treatment plants, steam generators, tanks, vessels, and other areas that are difficult to reach.

Buying Guide: Need assistance? Click here and send us your enquiry. We will be in-touch soon.

Available on backorder

Product successfully added to the Quote List

Revolutionary, Portable, 3D, Wireless Manhole Scanning Technology.

Perform swift inspections and surveys of pipelines, wet wells, manholes, sewer treatment plants, steam generators, tanks, vessels, and other areas that are difficult to reach.

Benefits & Features

Output can be used for structural assessment and pre/post rehabilitation analysis.

- Measurable Data

SPiDER collects millions of three-dimensional (3D) points during each manhole scan that provides engineering and survey quality information on manhole geometry and condition. Output can be used for structural assessment, pre and post rehabilitation analysis, hydrological surveys, as well as general condition assessment.

- Portability

SPiDER weighs less than 30 pounds and can be hand carried to difficult to access sites. Additionally, SPiDER does not require a truck or data/power cable for operational use. Scanning data is recorded on the unit.

- Tetherless Positioning

SPiDER can calculate its position in the manhole shaft by using its internal sensor data to measure its incremental motion. This technology frees manhole scanning from problems associated with inaccurate, poorly calibrated cable counters and poorly managed cables.

- Tablet Controlled

SPiDER can be operated with any tablet or computer which receives WI-FI to controls the scanner’s cameras and lights.

- 3D, Textured Point Clouds

SPiDER provides renderings of manhole geometry to provide three dimensional visualization that can

be imported into a wide range of 3D viewers.

- File Format Deliverables

3D MPEG Video (.MPG)

Point Cloud (.PLY) which can be converted to:

- Surface Model (.STL)

- CAD Model (.DXF)

- Virtual Model (.OBJ )

- Live Video

SPiDER provides a 190 degree field-of-view live video stream – making it an ideal tool for Infiltration and Inflow (I&I) studies which depend on live video to detect moving water.

Related products

Pipeline Inspection CCTV

Pipeline Inspection CCTV

Pipeline Inspection CCTV

P550C