Trelleborg Pipe Lining

Trelleborg Pipe Lining method is a cured-in-place pipe lining (CIPP) system.

Buying Guide: Need assistance? Click here and send us your enquiry. We will be in-touch soon.

Cured-In-Place Lining (CIPP) for Pipe Rehabilitation

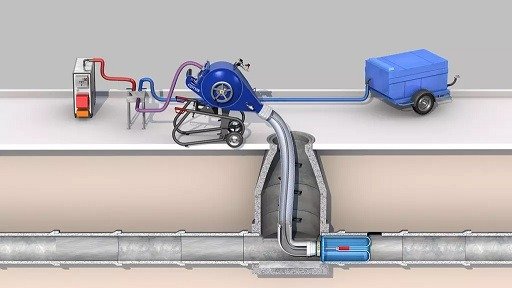

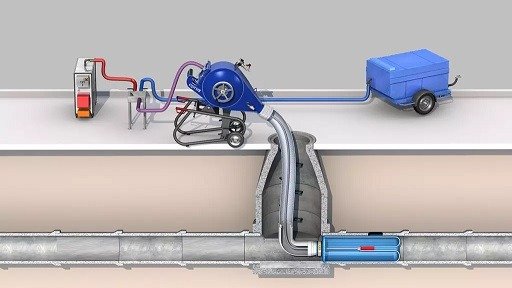

The Trelleborg Pipe Lining method is a cured-in-place pipe lining (CIPP) process used in trenchless pipe and sewer rehabilitation (“no-dig” applications). The start or end point can be a manhole, inspection hole or cleaning eye or a open cut pipe. It is possible to install the liner along channel diversions or invert bends at an angle up to 90 degrees. The basic condition is that there is enough space to place the inversion fitting of the inversion unit or water rig.

- Eco-friendly no-dig pipe renovation method

- Gives pipes another 50 years life span

- Saving time, money and CO² emission

Proven technology for trenchless pipe and sewer rehabilitation

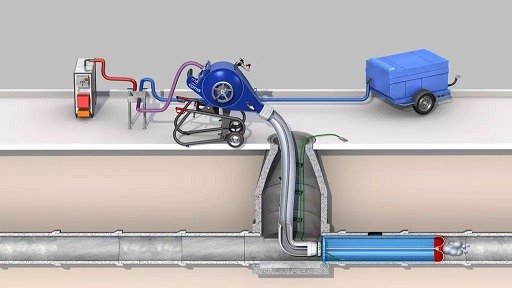

The rehabilitation of non-man-entry sewer lines with full-length CIPP liners has established itself as a sophisticated economical and technical alternative to traditional repair techniques involving digging up the ground. This method is meanwhile a proven and reasonable-cost solution for the basic renovation of service lines in need of repair and thus to extend their service lives for another life cycle of at least 50 years. A basic condition is that the materials used in CIPP operations are suitable for this type of application and that the installation process meets stringent quality criteria.

The Inversion Method

This process uses a flexible tube (= liner) of corrosion-proof synthetic and/or glass fibres, which is wetted inside with reaction resins and introduced into the host pipe run through a manhole, access pit or access eye with the help of an inversion unit. During this process the liner tube is inverted, so the resin wetted liner side (inside before inversion) is turned outside, away from the effluent and forced against the pipe wall

The curing process

The rehabilitation result

Application Areas

Pipe run direction |

In case of laterals: either from a lateral start point down to the lateral/main interface or from a main line start point down to the main/lateral interface |

Circular, egg-shaped and special sewer sizes |

Precondition: |

Applicable Damages |

|

Limitations |

|

Pipe Diameters | DN 30 - DN 1200 | 1,2" - 64" |

Connection Angles | 30° to 90° |

Certifications

Download

DrainLining Product Info (2020)